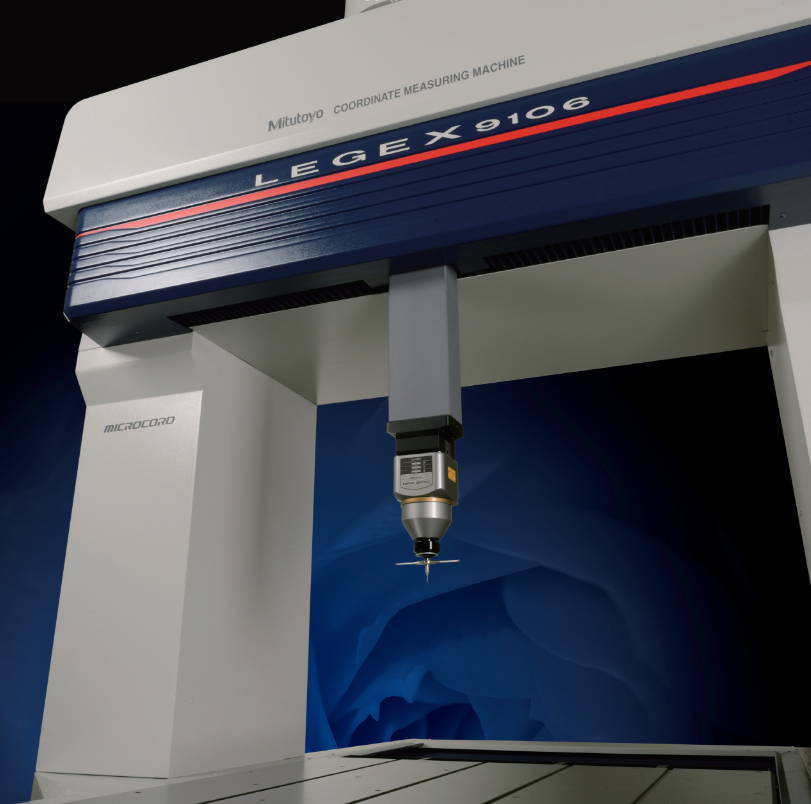

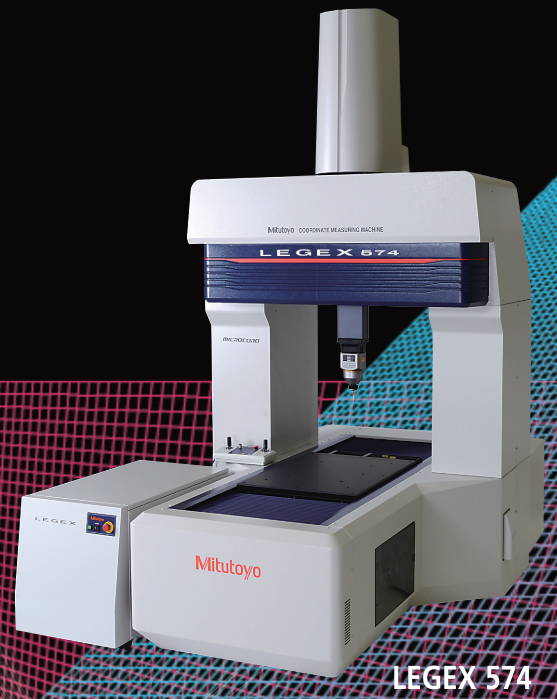

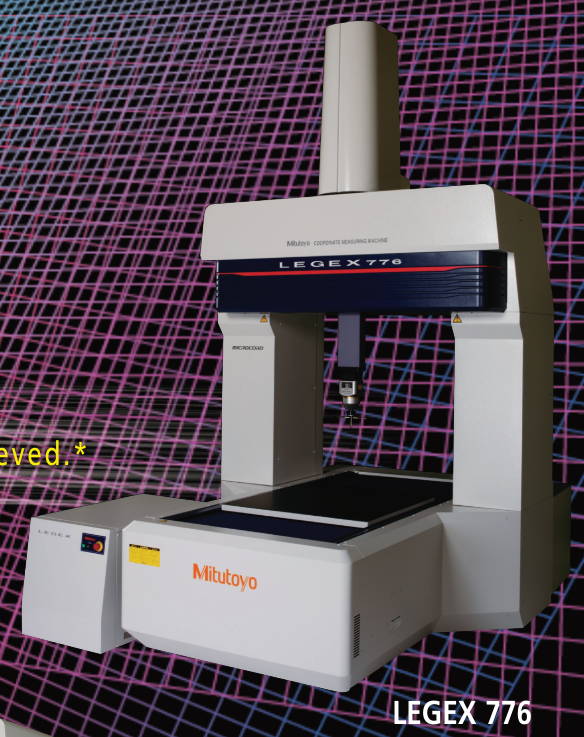

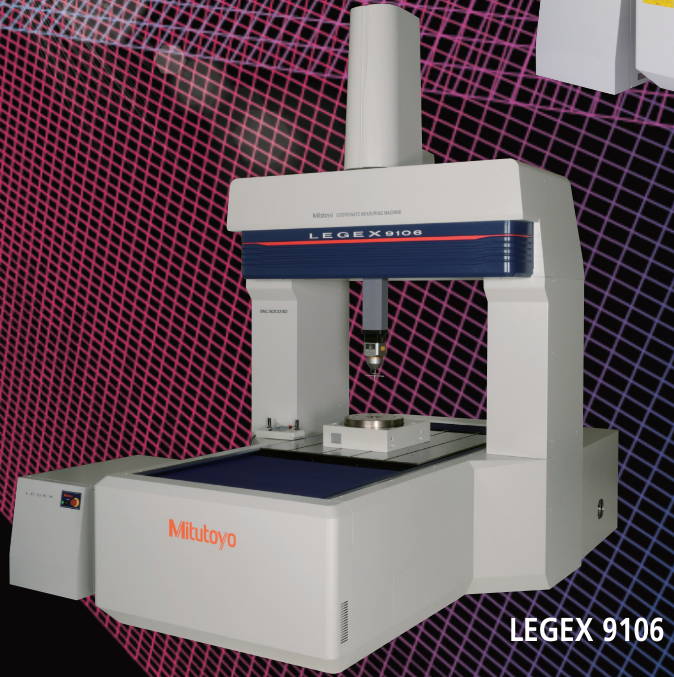

MICROCORD LEGEX Series

Ultra-high Accuracy CNC Coordinate Measuring Machine

The culmination of 80 years of Mitutoyo technology. Recognized as the world's ultimate high-accuracy measurement technology.

Precise + Effective + Absolute

Evolving technology Thorough analysis and elimination of error factors, PART ONE:

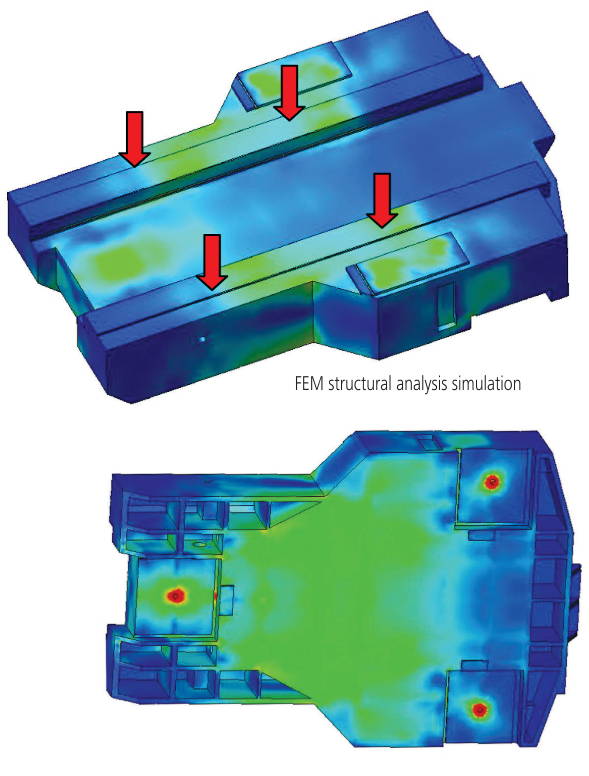

BASE DESIGN

High Rigidity

The base of the LEGEX is made from special spheroidal graphite ductile cast iron to a sealed-structure design that provides high rigidity and vibration attenuating characteristics. Mitutoyo engineers used FEM analysis during the design phase to optimize the final configuration and ensure outstanding geometric accuracy by minimizing deformations caused by normal machine operation.

*Spheroidal graphite ductile cast iron*

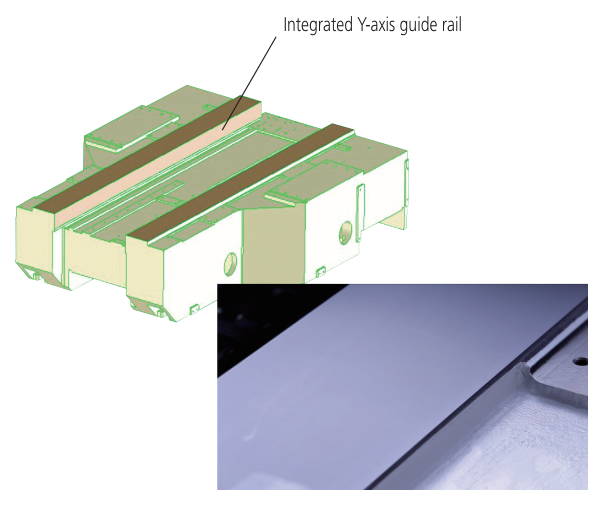

Integrated Y-axis guide rail

To further increase rigidity and thermal stability, the Y-axis guide rail

is integrated with the main unit base.

Ceramic plasma spraying for each axis sliding section

Ceramic plasma spraying is applied to sliding sections for the Y-axis guide rail, X-axis beam, and Z-axis spindle, creating surfaces suitable for highly accurate air-bearing operation. It also produces excellent corrosion resistance.

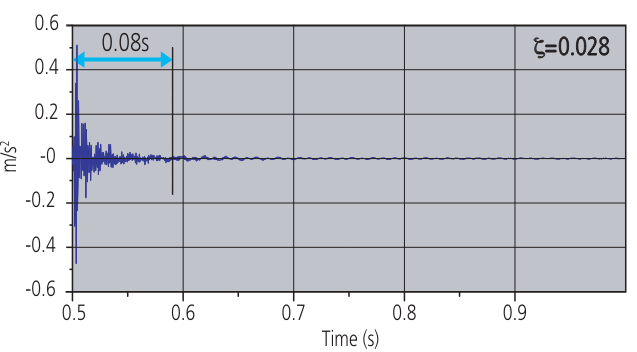

Vibration attenuation

The LEGEX structure quickly attenuates traverse-induced vibrations and so reduces any adverse effect on measurements.

This characteristic also allows ultra-high scanning accuracy to be realized.

WORKTABLES

Ceramic Coated is standard US product.

Evolving technology Thorough analysis and elimination of error factors, PART TWO:

CONSTRUCTION

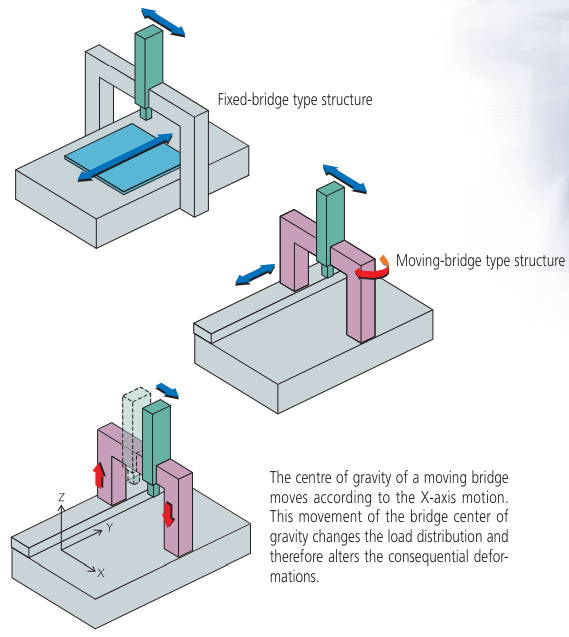

Pitch and yaw errors practically eliminated

The LEGEX uses a fixed-bridge type structure. This is the ideal CMM architecture and virtually eliminates pitch and yaw errors. Most other CMMs use a moving-bridge design with a single drive unit under the column, which tends to cause yawing and pitching during slide movements.

- Fixed-bridge type structure.

- Moving-bridge type structure.

- The center of gravity of a moving bridge moves according to the X-axis motion. This movement of the bridge center of gravity changes the load distribution and therefore alters the consequential deformations.

DYNAMIC ACCURACY

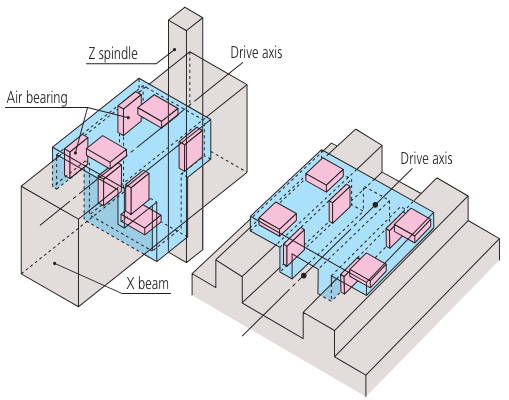

X- and Y-axis independence and a ‘center of gravity’ type drive system

The fixed-bridge design of the LEGEX allows the axes to operate totally independently. Movement of the X-axis slide does not change the loading on the Y-axis slide, and so does not cause deformation.

Also, the ‘center of gravity’ type drive system places the drive units near the center of gravity of each slide. This feature allows very high speed, highly accurate measurements by reducing inertia-induced deflections during acceleration and deceleration.

VIBRATION CONTROL

Isolating floor vibration

The LEGEX is hardened against floor induced vibration by use of ‘air-damped spring isolators’ with an auto-leveling function. This virtually eliminates factory floor vibrations from the entire machine structure.

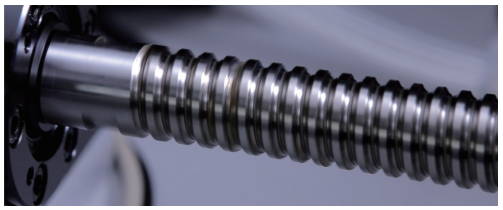

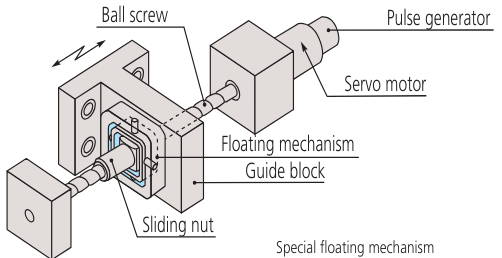

Floating mechanism reduces internal VIBRATION

To reduce the effects of internally generated vibration, the LEGEX uses a special floating mechanism to couple each ballscrew to its guide block. This isolates the slide from the servo motor as it turns the ballscrew and thus prevents transmission of motor vibrations, especially during acceleration and deceleration.

Evolving technology Thorough analysis and elimination of error factors, PART THREE:

LENGTH STANDARD

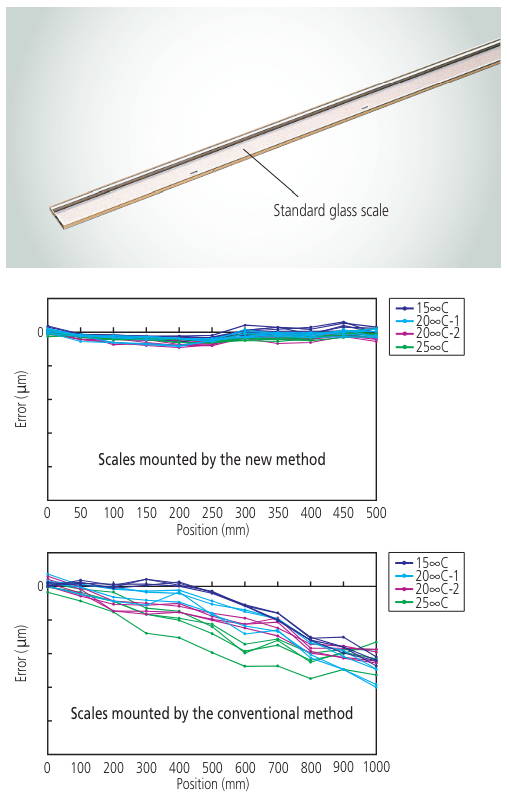

Linear glass scales with virtually zero thermal expansion coefficient

The LEGEX is equipped with crystallized-glass scales with a

resolution of 0.01μm and an ultra-low linear expansion coefficient of 0.01 x 10-6/K. This virtually zero thermal expansion coefficient means the LEGEX can maintain its extreme accuracy in spite of thermal changes.

The scales are also mounted in a unique new way that reduces the hysteresis error to 1/5 that of previous models. The graphs below show the reduction in hysteresis error that results from this new mounting method.

TEMPERATURE COMPENSATION

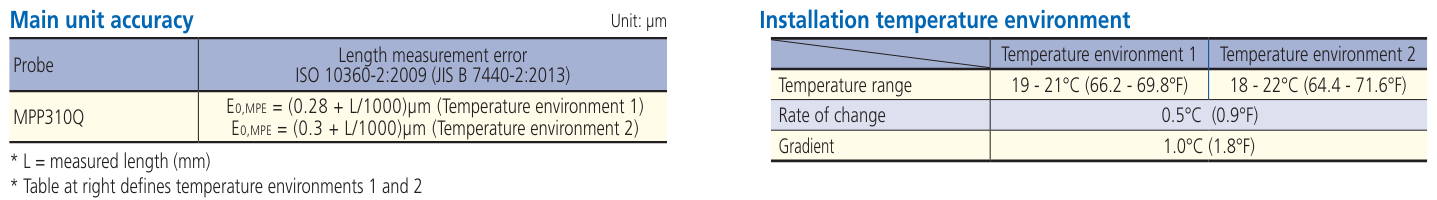

Effective over the 18ºC to 22ºC (64.4ºF to 71.6ºF) temperature range

While conventional very high accuracy CMMs require fairly strict temperature controlled environments, the LEGEX has been designed to improve the thermal stability of each component to minimize deformation. In addition, temperature sensors on each axis and for the workpiece itself detect temperature changes in real time and are used to compensate back to size at 20ºC.

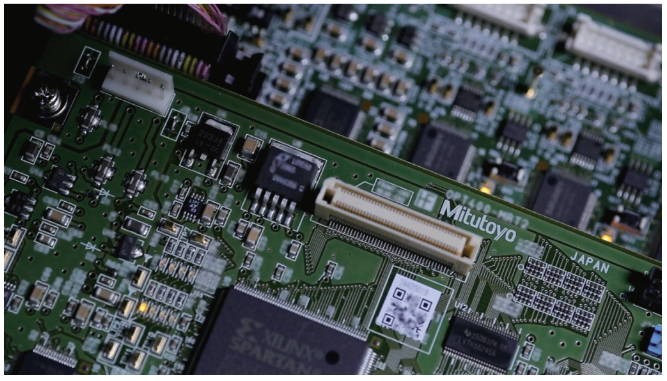

STATE-OF-THE-ART CONTROL

Our proprietary control unit has been upgraded with sophisticated control technology that uses a new algorithm. A newly developed high-resolution linear encoder is also used to achieve higher accuracy.

ZERO CERA BLOCK (LOW EXPANSION CERAMIC GAUGE BLOCK)

An optional accuracy checking accessory

Mitutoyo offers a special check standard that matches the characteristics of the LEGEX scales. This optional accessory uses ultra-low-expansion ceramic gauge blocks with a thermal expansion coefficient in the temperature range 20±1ºC less than 1/500 that of steel (0±0.02×10-6/K(20ºC)). Using this ZERO CERA BLOCK standard provides a customer with the means to check the measuring accuracy of their LEGEX at any time, and so gain insight into how often their machine should be calibrated and adjusted by Mitutoyo. All gauge blocks in the standard are measured by interferometer to 0.00001mm resolution in Mitutoyo’s Accredited Calibration Laboratory (JCSS No. 0030).

TEMPERATURE STABILIZED

An optional accuracy enhancing accessory

Generally speaking, temperature compensation and thermally insensitive materials can widen the usable range of ambient temperature and gradients. To eliminate a common source of temperature variation, the LEGEX incorporates a special air-server. In addition to the standard air cleaning and drying functions, this air server stabilizes the temperature of air drawn from the factory air supply to 20ºC±0.1ºC.

In combination with the machine-enclosure design and thermally insensitive glass scales, temperature-stabilized air supplied to the air bearings can produce the exceptional thermal isolation needed for low measuring uncertainties. This air supply is also used for the MPP-300 probe to provide stabilized scanning.

program

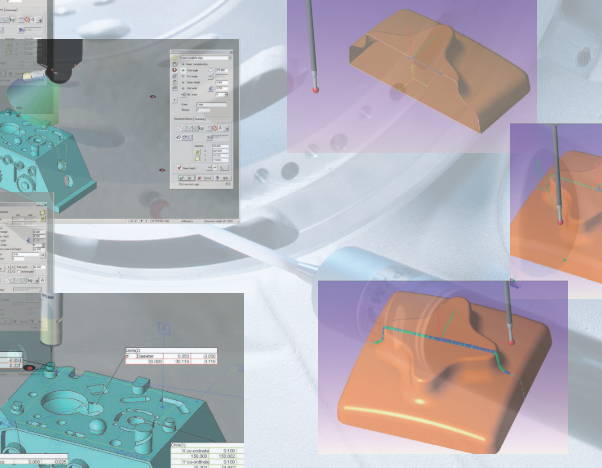

MCOSMOS

Mitutoyo Controlled Open System for Modular Operation Support

A wide variety of software modules for each manufacturing step, from design to production and to inspection, are available. In addition to a quality assurance module, they also include modules that support various types of CAD data processing, in-line measurement, data feedback, and process management.

System performance from every viewpoint

Performance features of standard software modules.

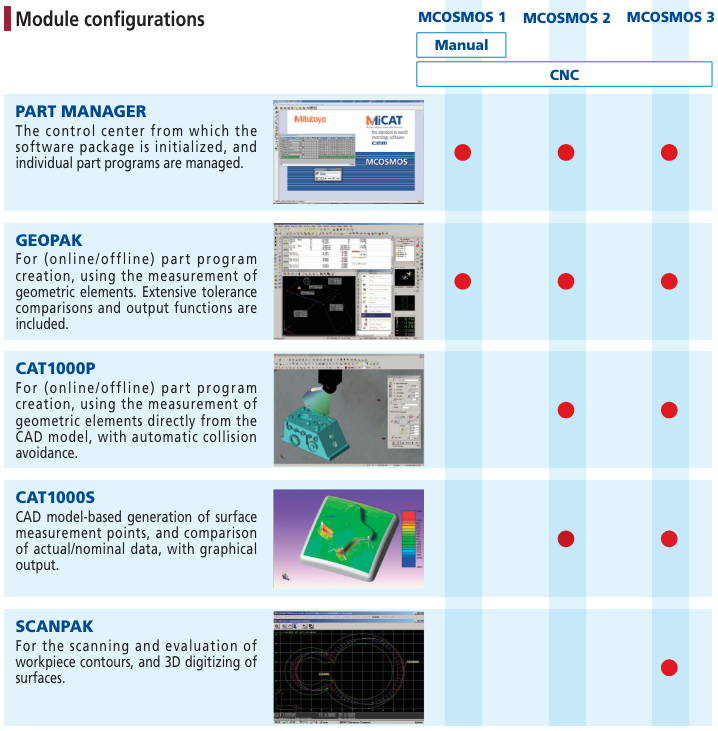

Module configurations

MCOSMOS has three module configurations, from the basic MCOSMOS 1 to the advanced MCOSMOS 3. This enables a choice of appropriate functionality for your current measurement applications now with the ability to expand, if needed, in the future.

Other optional software modules

A wide variety of optional software packages that meet customer needs is available, including MAFIS Express for evaluating the shape of an airfoil, GEARPAK for evaluating gear measurements, FORMPAK-CMM, ROUNDPAK-CMM, and the MeasurLink statistical processing program.

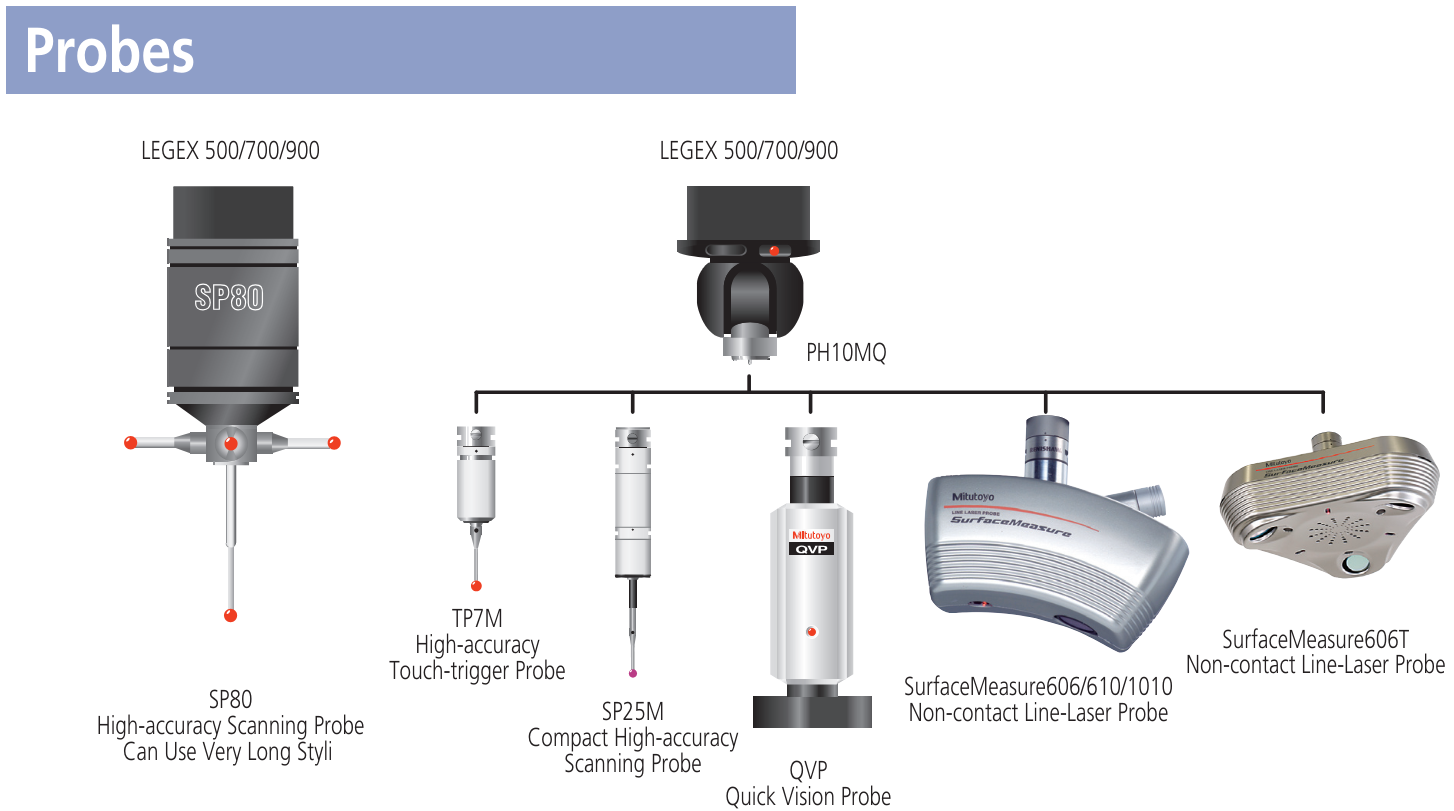

Probes and accessories

High accuracy combined with wide measuring range Best suited for highly accurate measurement of large workpieces

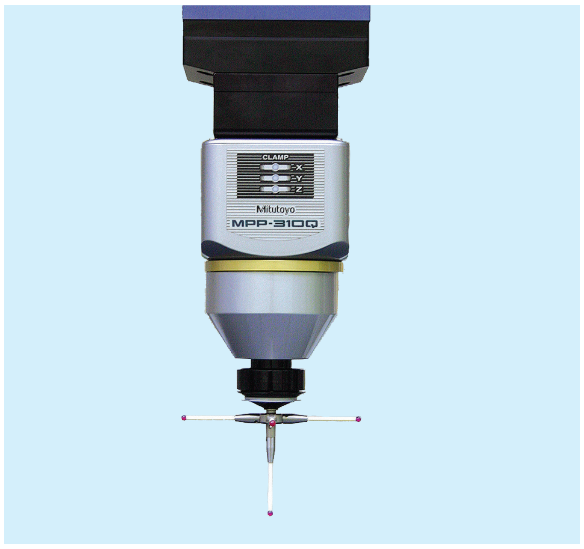

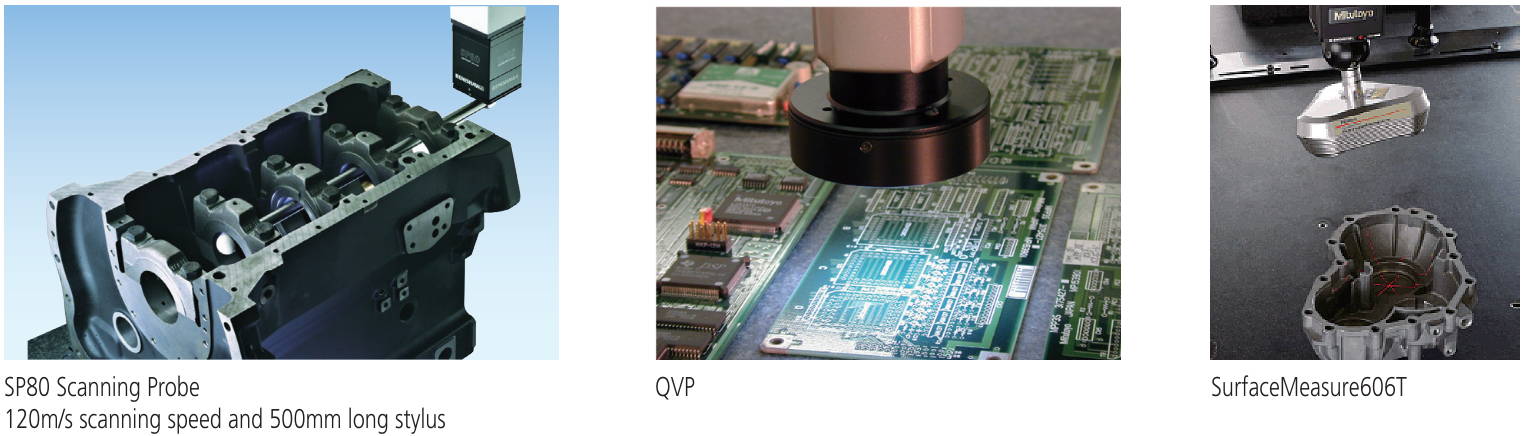

MPP-310Q

Ultra High-Accuracy Scanning

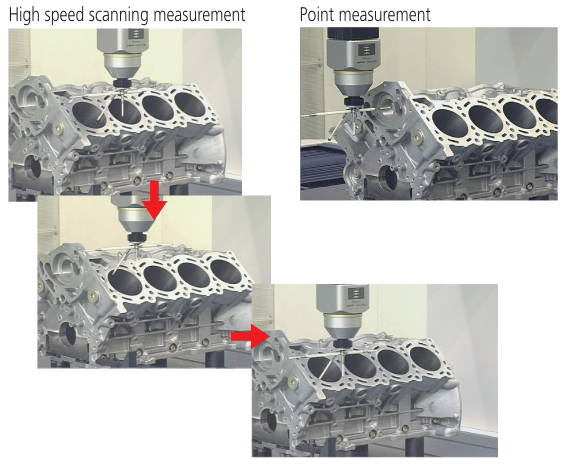

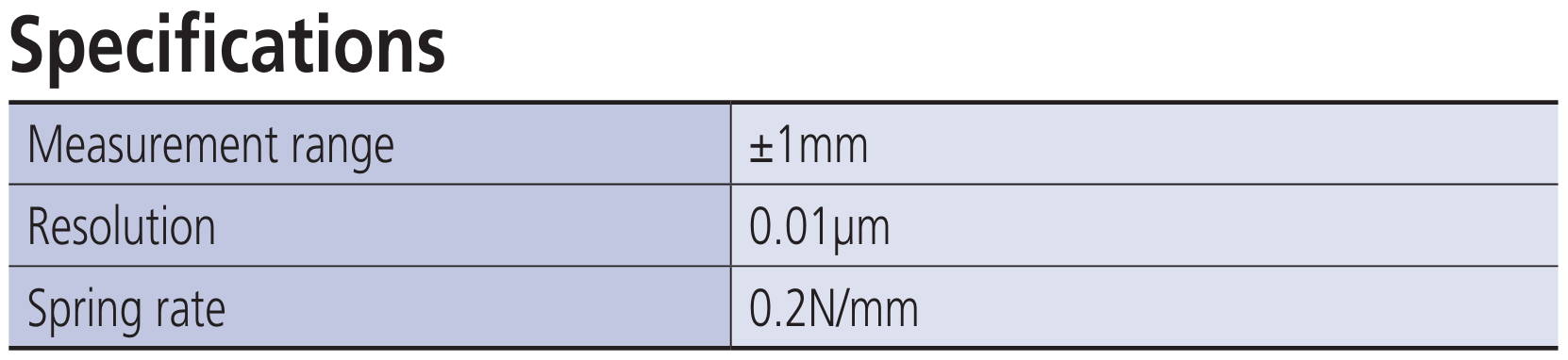

The MPP-310Q is a multi-functional probe designed for CNC coordinate measuring machines. It can not only perform a continuous path contact type scanning measurement [a measurement method that implements a collection of a large amount of coordinate data while traveling along a continuous path in contact with the workpiece] at V2≤0.3μm*, but also high-accuracy point measurement of ≤0.1μm, and data collection from a centering point measurement.

* V2 (VDI2617) filtering is used with a standard stylus: 20°C, reference displacement: 0.25mm, measurement speed: 3mm/sec, using a ø45 ring gage

Omni-directional scanning

The MPP-310Q has internal high-accuracy scales with a resolution of 0.01μm in each direction (X, Y, and Z axes), which makes it possible to read the stylus displacement in any direction. The air bearing employed in the sliding section of each axis helps provide this probe with minimum directionality.

Low measuring force

MPP-310Q can reduce its measuring force to a minimum of 0.03N so that it can even measure elastic workpieces such as resins, etc., without damaging them at all.

Fast scanning

MPP-310Q can perform fast scanning at 120mm/s. For example, it completes a measurement in just a few seconds even if it is required to measure an inside diameter of 100 mm using 1000 measurement points. In addition, measurement can be pursued effectively while changing the scanning speed, depending on the measurement accuracy required.

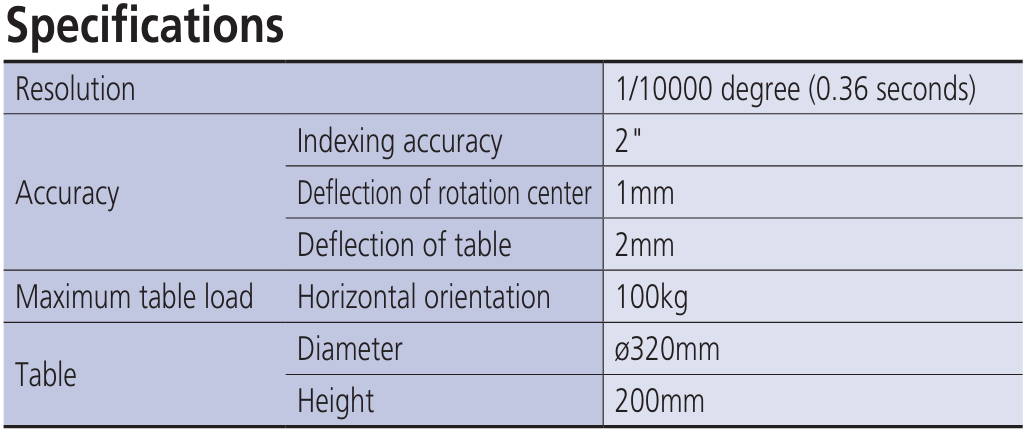

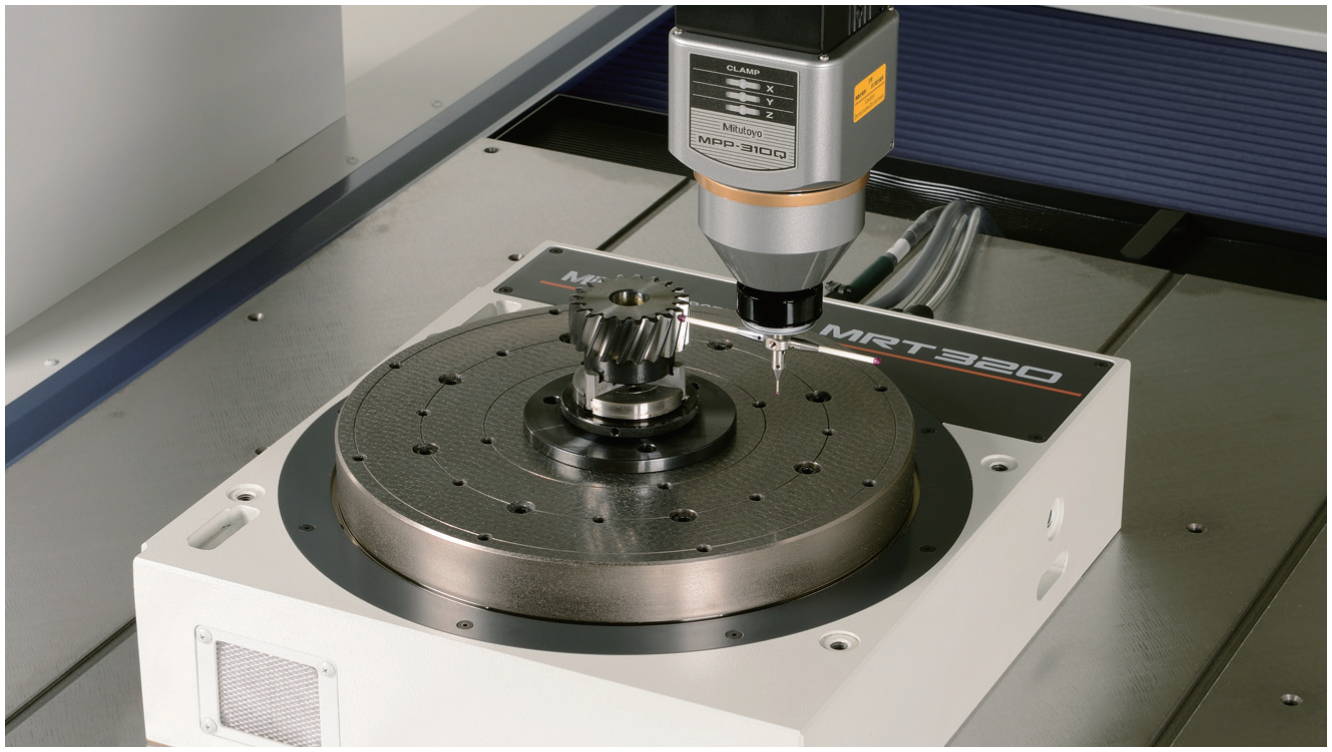

MRT320 Rotary table

The LEGEX can be used with the MRT320 rotary table as the 4th axis. It is very efficient for gear, cylinder cam and impeller measurements.

Introduction to LEGEX 12128

Note: This machine incorporates a main unit Startup system (relocation detection system), which disables operation when an unexpected vibration is applied or the machine is relocated. Be sure to contact your nearest Mitutoyo Sales Office prior to relocating this machine after initial installation.

Our Mission & Vision

Whatever your challenges are, Mitutoyo & our team at GreatGages.com supports you from start to finish!

Mitutoyo is not only a manufacturer of top quality

measuring products but one that also offers qualified

support for the lifetime of the equipment, backed

by comprehensive services that ensure your staff can

make the very best use of the investment.

Apart from the basics of calibration and repair,

Mitutoyo offers product and metrology training,

as well as IT support for the sophisticated software

used in modern measuring technology.

Mitutoyo can also design, build, test and deliver measuring solutions and even, if deemed cost-effective, take your critical measurement challenges in-house on a sub-contract basis.

Need a Quote?

Give us a call or mail us by anytime, we strive to answer all inquiries within 24 hours on business days. We will be happy to answer any and all of your questions.

Toll Free: 866-460-1942

Email: sales@greatgages.com