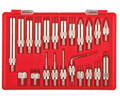

indicators dial

precision tolerance measuring

A Dial Indicator provides a dial display similar to a clock face with clock hands; the hands point to graduations in a circular scales on the dial which represent the distance of the probe tip from a zero setting. The internal works of a mechanical dial indicator are similar to the precision clockworks of a mechanical wristwatch, employing a rack and pinion gear to read the probe position, instead of a pendulum escapement to read time.

The side of the indicator probe shaft is cut with teeth to provide the rack gear. When the probe moves, the rack gear drives a pinion gear to rotate, spinning the indicator "clock" hand.

Springs preload the gear mechanism to minimize the backlash error in the reading. Precise quality of the gear forms and bearing freedom determines the repeatable precision of measurement achieved. Since the mechanisms are necessarily delicate, rugged framework construction is required to perform reliably in harsh applications such as machine tool metalworking operations, similar to how wristwatches are ruggedized.

Indicators may be used to check the variation in tolerance during the inspection process of a machined part, measure the deflection of a beam or ring under laboratory conditions, as well as many other situations where a small measurement needs to be registered or indicated.

Various names are used for indicators of different types and purposes, including dial gauge, clock, probe indicator, pointer, test indicator, dial test indicator, drop indicator, plunger indicator, and others.