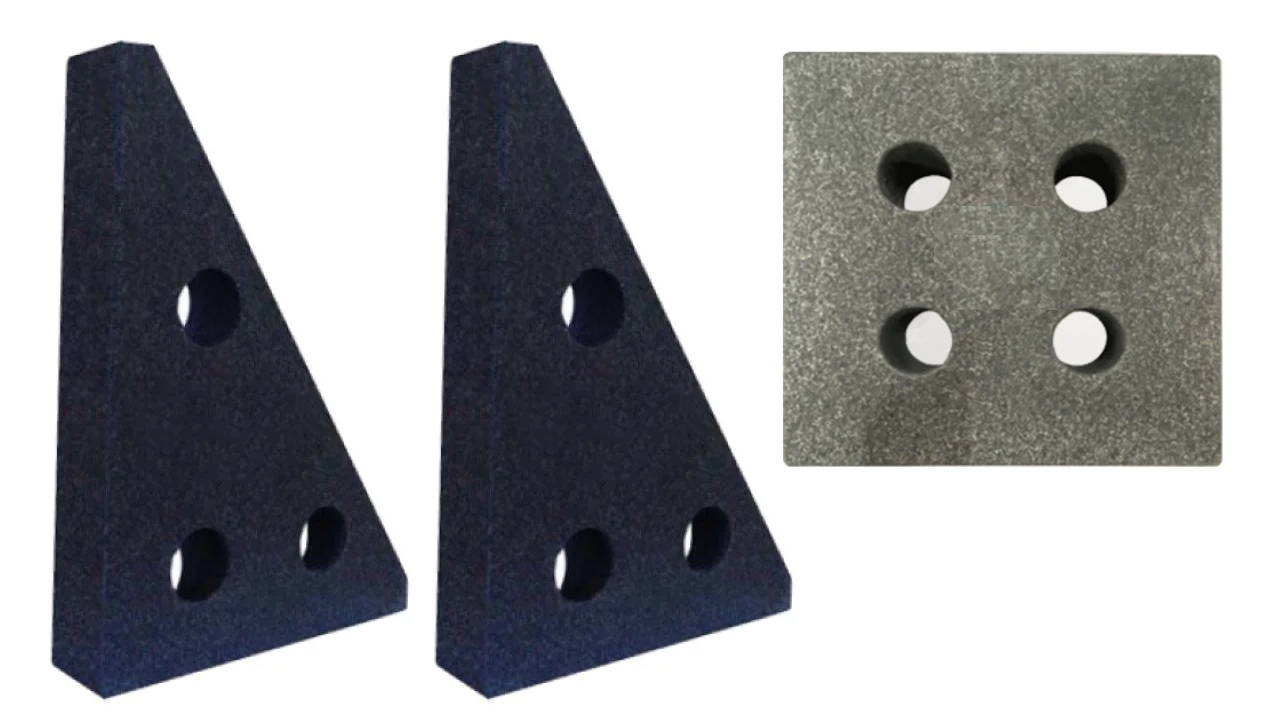

Granite squares

dimensional stability

Granite Tri-Squares and Granite Master Squares are precision measuring tools used in metrology, engineering, and machining applications. They are both made of high-quality granite material that provides excellent dimensional stability, durability, and resistance to wear, corrosion, and thermal expansion.

Granite Tri-Squares are three-sided square tools that have precision ground surfaces for accurate measurement of 90-degree angles. It consists of a base with two perpendicular sides and a third perpendicular side that forms a 45-degree angle with the base. The three sides are precision ground and polished to a high degree of flatness and parallelism, which makes the tool ideal for checking the squareness of workpieces, machine setups, and tooling.

Granite Master Squares are four-sided square tools that has four precision ground surfaces for accurate measurement of 90-degree angles. It consists of a base with two perpendicular sides and two additional perpendicular sides that are parallel to each other. The four sides are precision ground and polished to a high degree of flatness and parallelism, which makes the tool ideal for checking the squareness of large workpieces, machine beds, and assembly fixtures.

Both Granite Tri-Squares and Granite Master Squares are typically used in precision machining, toolmaking, and inspection applications. They provide a high degree of accuracy and repeatability, which makes them essential tools for ensuring that machined parts and assemblies meet the required specifications and tolerances. Additionally, they are durable and long-lasting, which makes them a cost-effective investment for any workshop or manufacturing facility.