MICROMETERS STANDARD

precision THICKNESS measuring

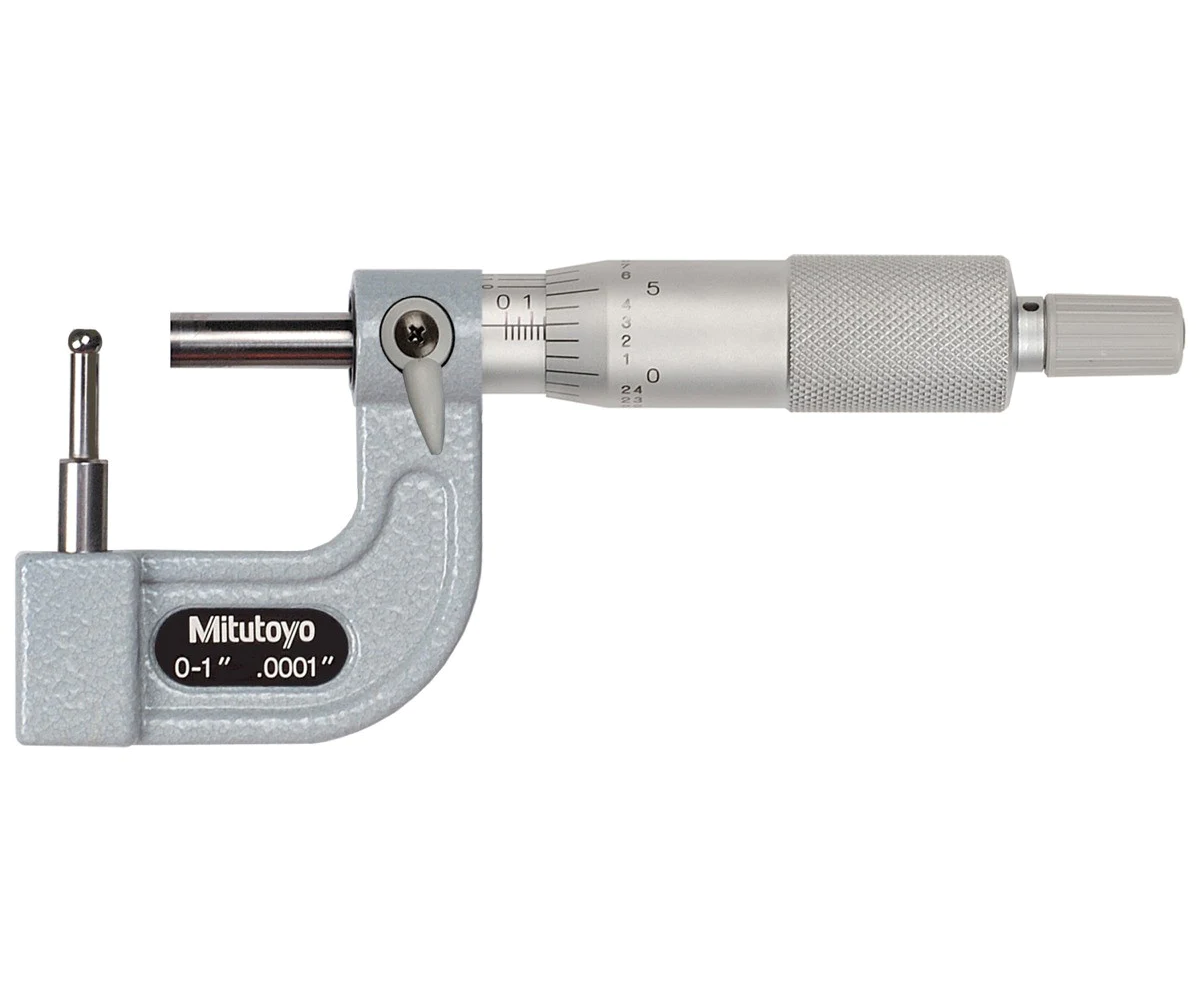

Mechanical micrometers are precision measuring instruments used to measure the thickness or diameter of objects with high accuracy and repeatability. They consist of a frame, a measuring spindle, an anvil, and a thimble that is rotated to advance or retract the spindle. The spindle contacts the object being measured, while the anvil provides a stable reference point.

Mechanical micrometers are known for their accuracy, durability, and ease of use. They are commonly used in manufacturing, machining, and inspection processes to ensure that components meet exact specifications. The micrometers come in a variety of models with different ranges and resolutions, allowing users to select the right tool for their specific application.

Some of the features of mechanical micrometers include a smooth, friction-free operation, a quick and easy zero-setting capability, and a clear and easy-to-read scale or dial that displays the measurement in either inches or millimeters. They are typically made of high-quality materials such as stainless steel, which makes them durable and resistant to wear and tear.

Mechanical micrometers are ideal for measuring the thickness or diameter of flat, cylindrical, or curved objects, as well as for measuring the depth of holes or recesses. They are suitable for both internal and external measurements and are often used in combination with other measuring instruments such as vernier calipers and depth gauges.

Overall, mechanical micrometers are a reliable and essential tool for anyone who needs to measure the thickness or diameter of objects with precision and accuracy. Their simple and robust design, combined with their accuracy and ease of use, makes them a popular choice for a wide range of industrial and mechanical applications.