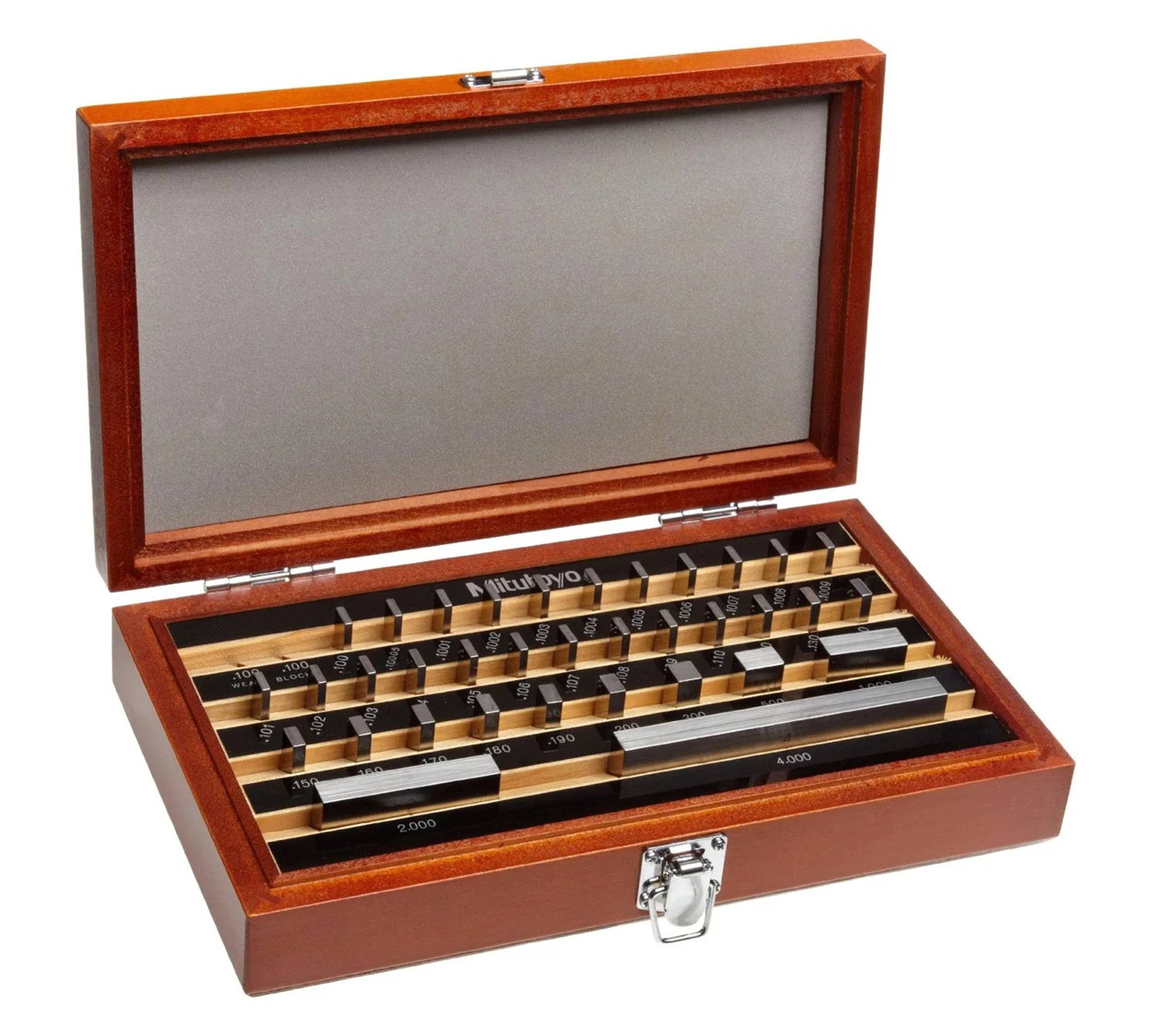

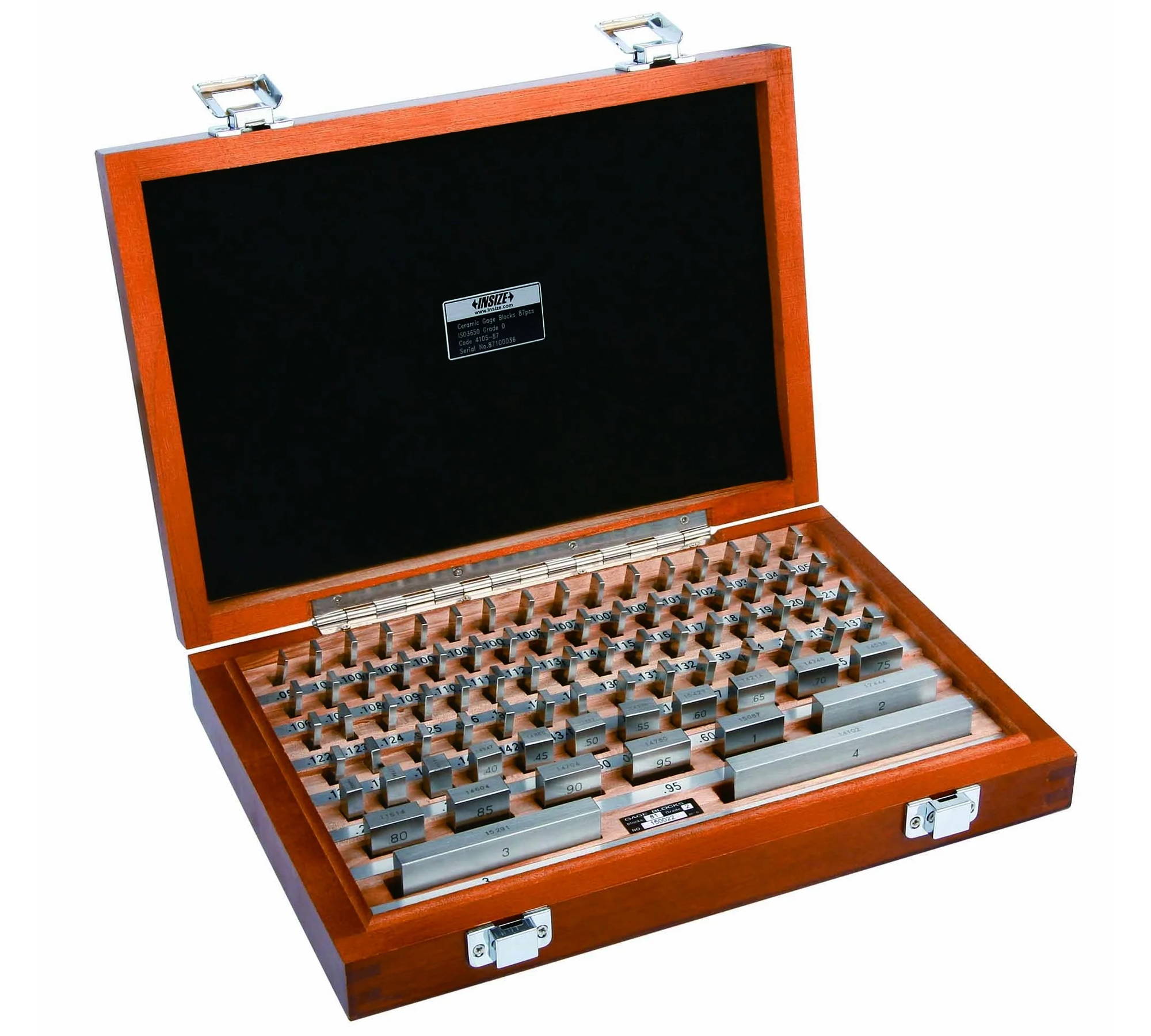

gage blocks

GAGE BLOCKS FOR CALIBRATION AND INSPECTION

Gage blocks are precision measurement tools used to calibrate and inspect other measuring instruments. They are typically made of high-quality steel, ceramic, or tungsten carbide, and come in a variety of shapes and sizes.

An important feature of gage blocks is that they can be joined together with very little dimensional uncertainty. The blocks are joined by a sliding process called wringing, which causes their ultra-flat surfaces to cling together. A small number of gage blocks can be used to create accurate lengths within a wide range.

Gage blocks are designed to be extremely accurate, with tolerances as small as a few millionths of an inch. They are used to set up or calibrate various measurement devices, such as micrometers, dial indicators, and height gauges, and to ensure that they are measuring accurately.

Gage blocks are an essential tool in many manufacturing and engineering industries, and are commonly used in applications such as automotive manufacturing, aerospace, and medical device production.