In the world of manufacturing, precision and quality control are paramount. In this age of technology and innovation, having the right tools to manage and analyze data is essential to achieving and maintaining high-quality standards. Mitutoyo's MeasurLink SPC (Statistical Process Control) Software stands as a powerful ally for manufacturers across various industries, offering a comprehensive solution to data collection, analysis, and quality management.

As a client / server solution, Mitutoyo's MeasurLink gives you the performance you need through distributed processing. Combined with a multi-user relational database,

MeasurLink delivers a safe and organized data warehousing system making quality data available for viewing and analysis by any member of the production, engineering, and managerial staff throughout your company. Inspection in the factory produces data for analysis, corrective action, and various reporting needs. As the backbone of your quality efforts, MeasurLink is guaranteed to reduce your production costs and increase your bottom line.

To shop our Mitutoyo Measurlink SPC Software Selection, Click Here.

Click Here to view MeasurLink SPC Software Videos.

Click Here to view MeasurLink SPC Software PDF Brochure.

Performance through Distributed Processing

Performance through Distributed Processing

At its core, Mitutoyo's MeasurLink is a client/server solution that leverages distributed processing to deliver exceptional performance. This capability ensures that data processing is efficient and responsive, even in demanding manufacturing environments. Whether you're measuring dimensions, inspecting components, or analyzing production data, MeasurLink provides the reliability and speed required for real-time decision-making.

Organized Data Warehousing for Quality Excellence

One of MeasurLink's standout features is its ability to create a secure and organized data warehousing system. This system stores quality data in a structured manner, making it accessible to anyone within the organization who needs it. From production staff to engineering and management teams, MeasurLink ensures that quality data is readily available for viewing and analysis.

Enhancing Production Efficiency

Quality control and data analysis go hand in hand. MeasurLink enables manufacturers to monitor and manage the quality of their products effectively. Inspection in the factory generates valuable data for analysis, corrective actions, and reporting. As the backbone of your quality efforts, MeasurLink not only enhances product quality but also reduces production costs, ultimately increasing your bottom line.

Mitutoyo MeasurLink SPC Software Selection

Mitutoyo MeasurLink offers a range of software editions to suit your specific needs. Here are some key editions and features:

-

Real-Time Standard: This edition supports real-time data collection, featuring live SPC charts that alert operators to deviations. It provides essential tools for monitoring variable and attribute inspections, ensuring process control and minimizing defects.

-

Real-Time Professional: Building on the Standard edition, this version offers advanced capabilities, including support for data filters, import templates, and DDE (Dynamic Data Exchange) DAQ sources. It empowers users with comprehensive analysis tools and reports for quality control and process improvement.

-

Real-Time Professional 3D: For those who require a 3D perspective, this edition allows you to view workpieces using 3D CAD data. It adds depth to your analysis, especially when working with complex parts.

-

Process Analyzer: This powerful supervisory tool lets you view, analyze, and report on data collected at any Real-Time station on the network. It provides additional charting options and management-friendly reports for a deeper understanding of your manufacturing process.

-

Process Manager: Ideal for centralized monitoring, this edition enables you to oversee information from all MeasurLink data collection terminals networked on the shop floor. It enhances visibility and control over your quality operations.

Advantages of Attributes - P Count

MeasurLink includes tools for attribute control, such as the p chart, which is used to control the fraction or proportion of non-conforming items. This charting method is invaluable for monitoring processes involving go/no-go gaging, visual inspection, varying sample sizes, and more. It aids in supplier quality management and rapid response to quality issues.

AS9100 Conformance for Aerospace Industry

For the aerospace industry, MeasurLink supports AS9100 requirements, offering features such as first article inspection (FAI) view, compliance with AS9102 requirements, and comprehensive reporting capabilities. It streamlines quality assurance processes in line with industry standards.

FDA Compliance for Medical Industry

MeasurLink understands the rigorous standards of the medical industry and offers robust support for FDA 12 CFR Part 11 compliance. It ensures electronic signatures, audit trails, and documentation requirements are met for FDA-regulated manufacturers.

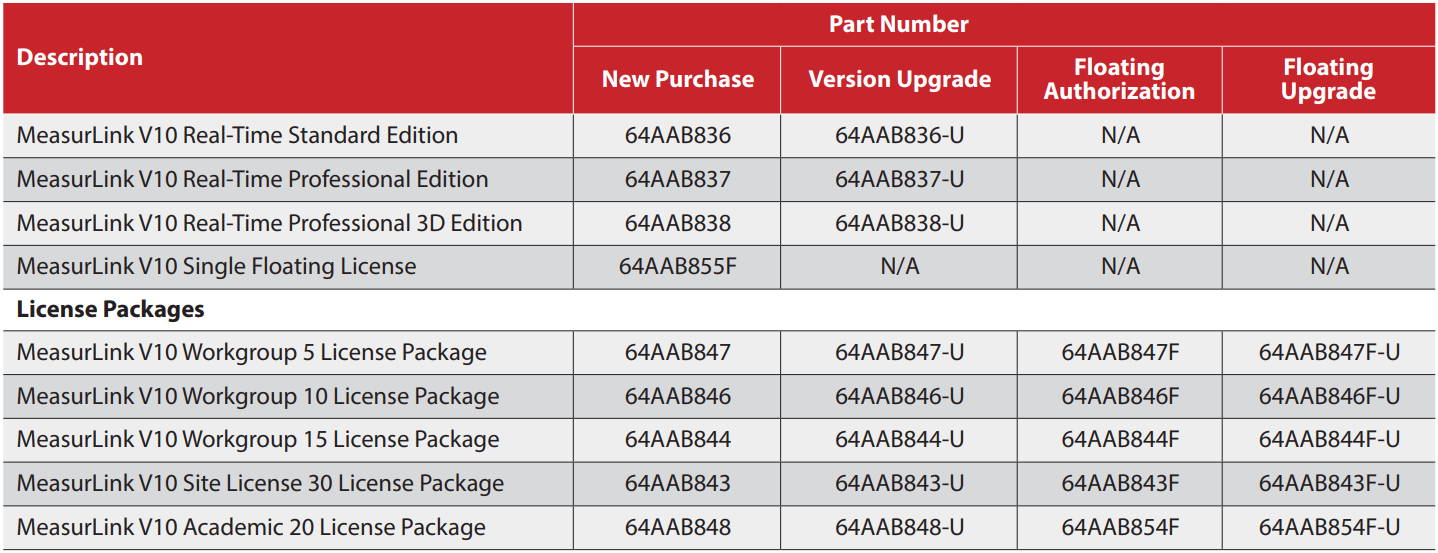

Flexible Licensing Options

Flexible Licensing Options

Mitutoyo offers flexible licensing options, including workgroup licenses for multi-license purchases, single floating licenses, standalone licenses for specific applications, and academic licenses for research and educational institutions. This flexibility allows businesses to tailor their software packages to their exact needs.

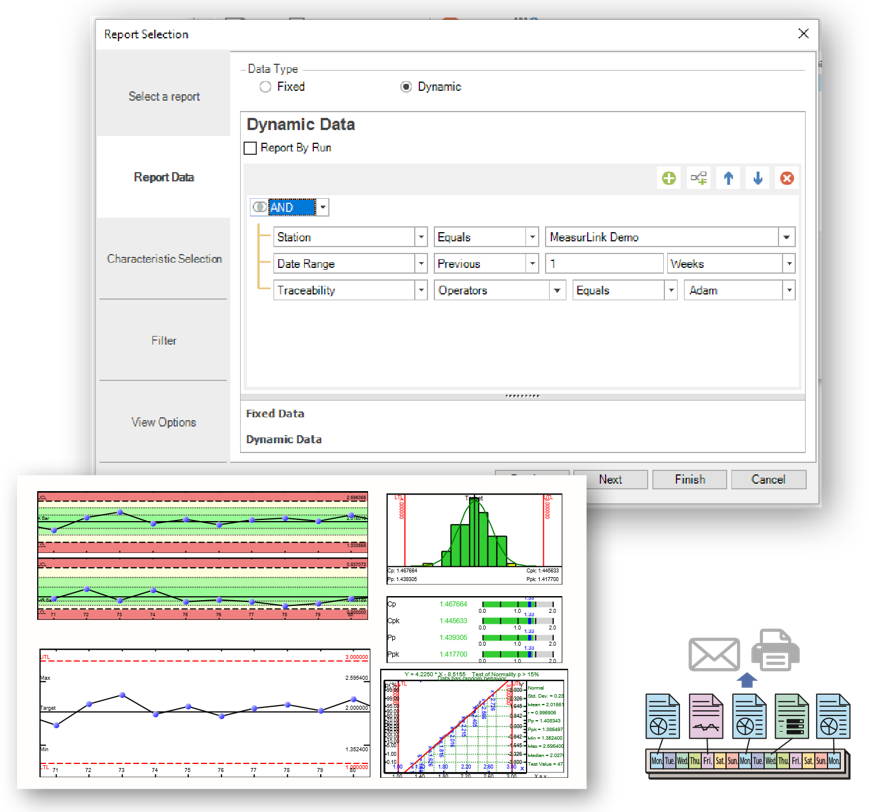

Collection Scheduler and Report Scheduler

MeasurLink includes tools like the Collection Scheduler, which helps operators stay on top of timed measurement schedules. It uses visual cues and alerts to ensure measurements are taken on time. Additionally, the Report Scheduler automates report distribution, saving engineers valuable time by generating reports on a predefined schedule.

Security and Windows Active Directory Support

Security Center in MeasurLink provides robust user management and permissions control. It also supports Windows Active Directory integration, ensuring authorized users have the proper rights automatically upon login.

Conclusion: Elevate Your Quality Control with Mitutoyo's MeasurLink

In the ever-evolving landscape of manufacturing and quality control, Mitutoyo's MeasurLink SPC Software stands out as a comprehensive and adaptable solution. Whether you're in aerospace, automotive, plastics, or the medical industry, MeasurLink offers the tools you need to achieve and maintain the highest standards of quality. With its distributed processing, data warehousing, and advanced analysis capabilities, MeasurLink empowers manufacturers to make informed decisions, reduce costs, and enhance product quality. It's the key to achieving excellence in the world of manufacturing.

To shop MeasurLink, Click Here.

To learn more about Mitutoyo's MeasurLink SPC Software and find the right edition for your needs, Click Here.